At the recent GEAPS (Grain Elevator & Processing Society) conference and expo, I attended as a member of the press. I promised to write an article about how to make grain silo operations carbon neutral. Sugar cane plants run on the agricultural waste generated from cutting down the sugar cane. After the stalks are crushed to remove their sugar juice the waste is used to make steam and then electricity to run the processing plant with centrifuges. Grain silos are very tall and there are many wind turbines on the prairie so they could put a turbine on top of the silos. So by burning agricultural waste, wind turbines, solar panels to make electricity along with energy use reduction improvements an operation could be carbon free. If they still couldn’t get there they could purchase carbon offsets. More to come after our reporting at Greenbuild 2021 in San Diego. We’ll be following the carbon and sustainability tracks.

Here’s a recent release from ADM,

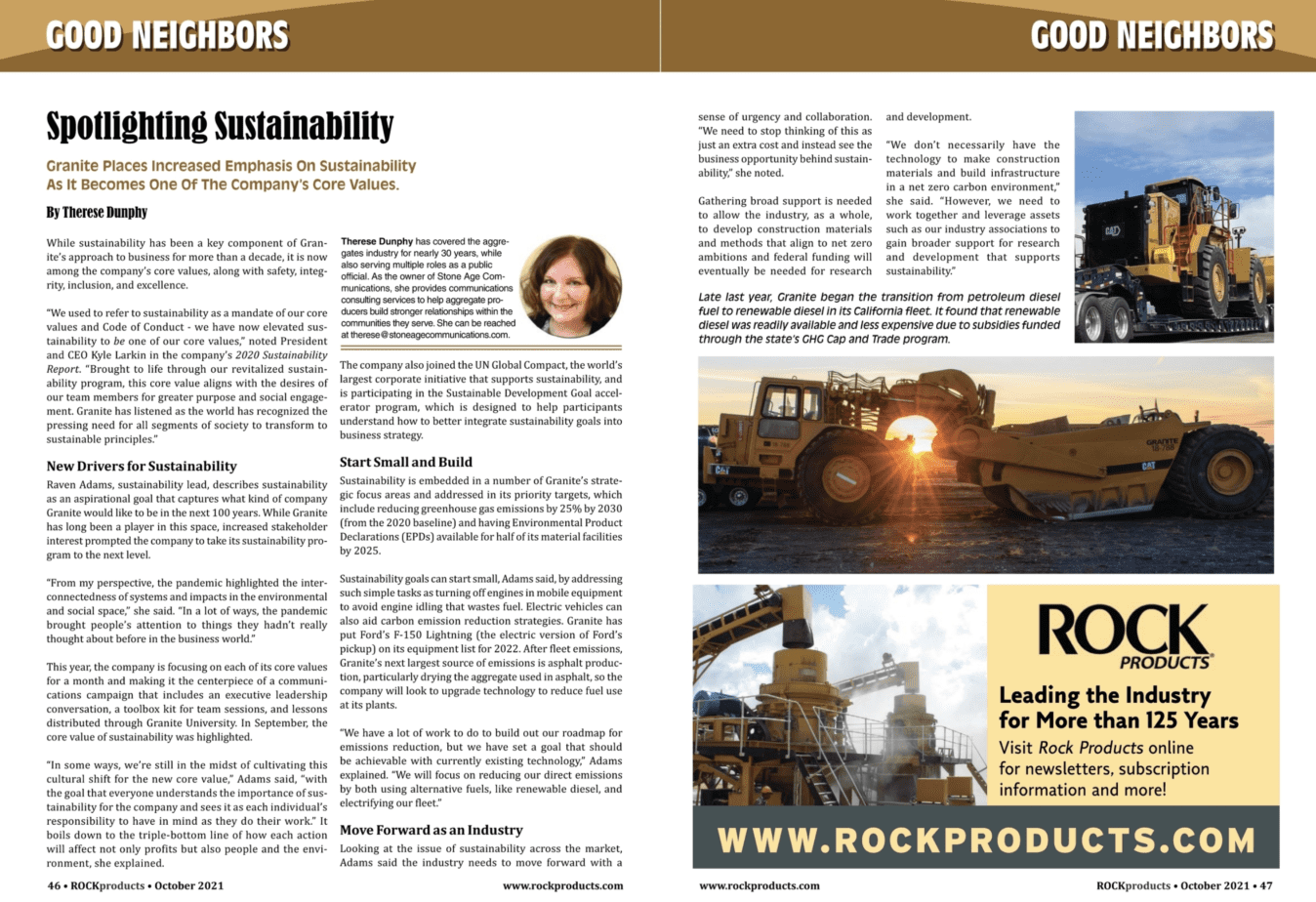

ADM’s US Flour Milling Operations Reach Carbon Neutrality

Image courtesy of ADM

American agribusiness Archer Daniels Midland (ADM) has completed a project to reach carbon neutral status at its 22 flour mills across the United States, a recent company release announced. The changes were accomplished by increasing the energy efficiency of the facilities, acquiring renewable energy certificates, and separating carbon dioxide at its commercial carbon capture and storage facility.

“Consumers increasingly expect their food to come from companies that share their values,” Todd Kruse, president, Milling & Baking Solutions for ADM. “ADM in proud to position as a trusted and capable partner in delivering responsibly and sustainably sourced ingredients that meet heightened consumer expectations. We know that our downstream customers are interested in reducing the carbon footprint of their supply chains, and we are eager to help them meet their goals with our net carbon neutral milling network.”